Car industry to massively overshoot global emissions targets without 'drastic action'

Manufacturers must clean up supply chains, says report

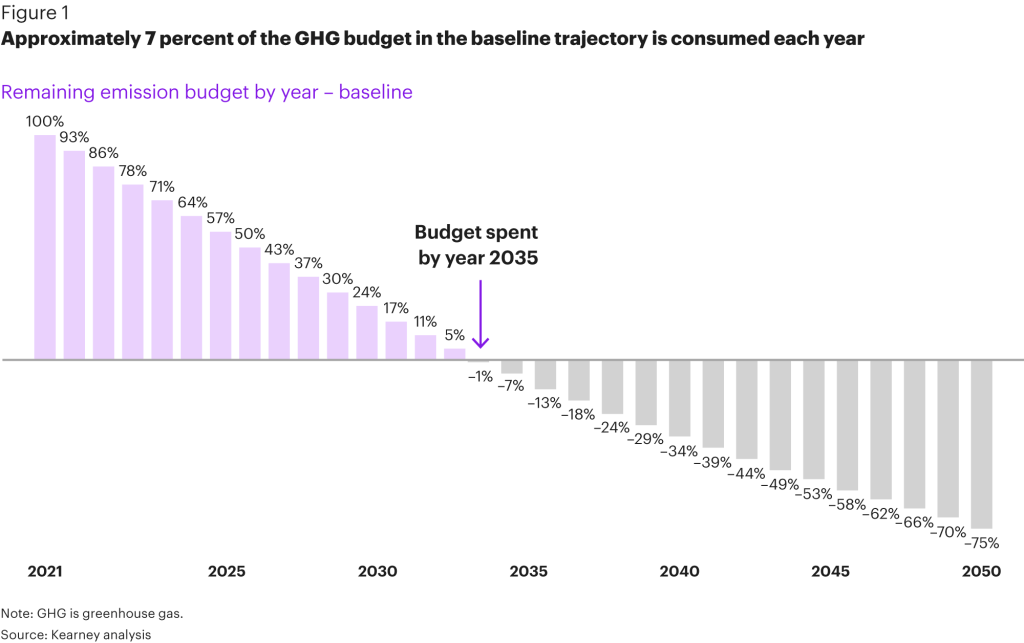

The global car industry will spend its entire carbon emissions budget by 2032 and overshoot it by some 75% by 2050 unless it takes drastic action to cut greenhouse gases, a new report warns.

The report from management consultancy Kearney and commissioned by electric vehicle manufacturers Polestar and Rivian outlines the titanic battle the motor industry faces to keep emissions below the targets laid out in the 2015 Paris climate agreement.

Total adoption of pure-electric vehicles and a 100% conversion of the global energy mix to fossil-free sources will not be enough to hit the target, it warns; a major initiative will also be needed to reduce the emissions of automotive supply chains.

The path the industry faces is “challenging”, says the report.

As per the Paris climate agreement, humanity has a remaining “budget” of around 500 gigatons of greenhouse gas emissions to prevent global temperatures rising by more than 1.5 degrees Celsius.

Assuming that passenger vehicles continue to account for around 15% of global emissions, the motor industry has a budget of 75-80 gigatons remaining, which, based on its current trajectory, will be entirely spent by 2032.

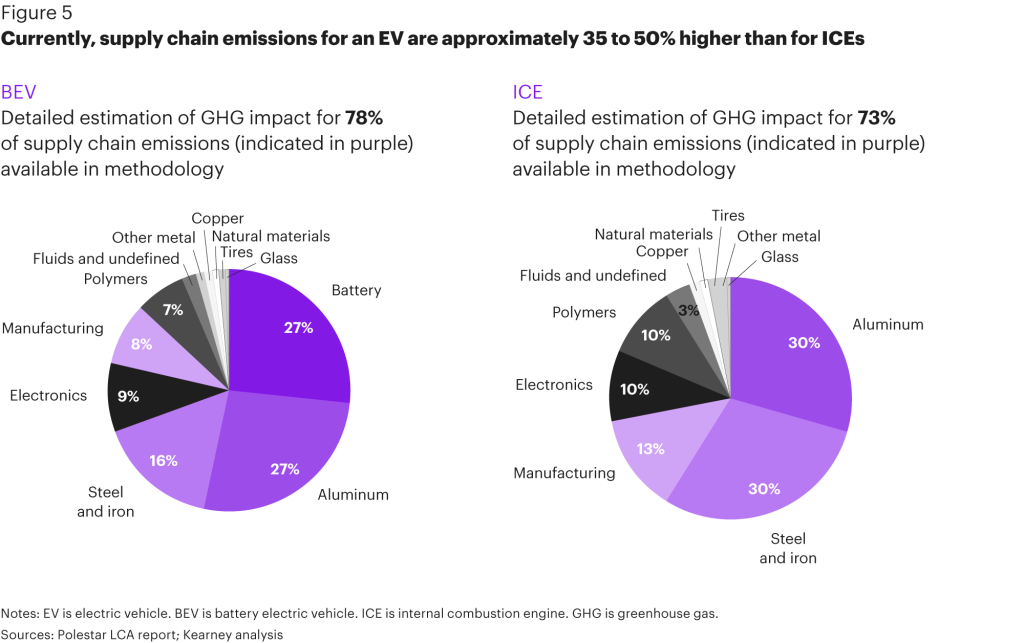

Three major offensives (or “levers”) are required, according to the report, in order for the car industry to stay within its emissions budget and, wildly optimistic though they are, even if all three are followed through successfully, the global motor manufacturing industry will still only barely avoid overshooting its budget.

The first lever involves an “aggressive” level of battery-electric vehicle adoption, with EV sales growing from the current level of 6% globally to 100% by 2032.

The second lever would see all countries shifting to a 100% fossil-free energy mix by 2033 in order to reduce the CO2 impact of vehicle charging.

“The shift to electric powertrains is only as clean as the power source used to charge the vehicle,” the report points out.

It claims that based on today’s global average of a 39% fossil-free electricity mix, running an electric vehicle has the potential to generate a reduction of 30-50 tons of CO2 versus a combustion-powered car, equating to a 35-46% reduction in lifetime emissions per vehicle, with significant regional variations.

While that represents a substantial emissions improvement over a combustion-powered car, even if the entire global car fleet were battery-electric and the energy grids used to power it were entirely fossil-fuel free, it would still yield an emissions overshoot of around 25%.

“Every year that passes without significant reductions is an opportunity lost and a setback from which we will have to work even harder to recover.”

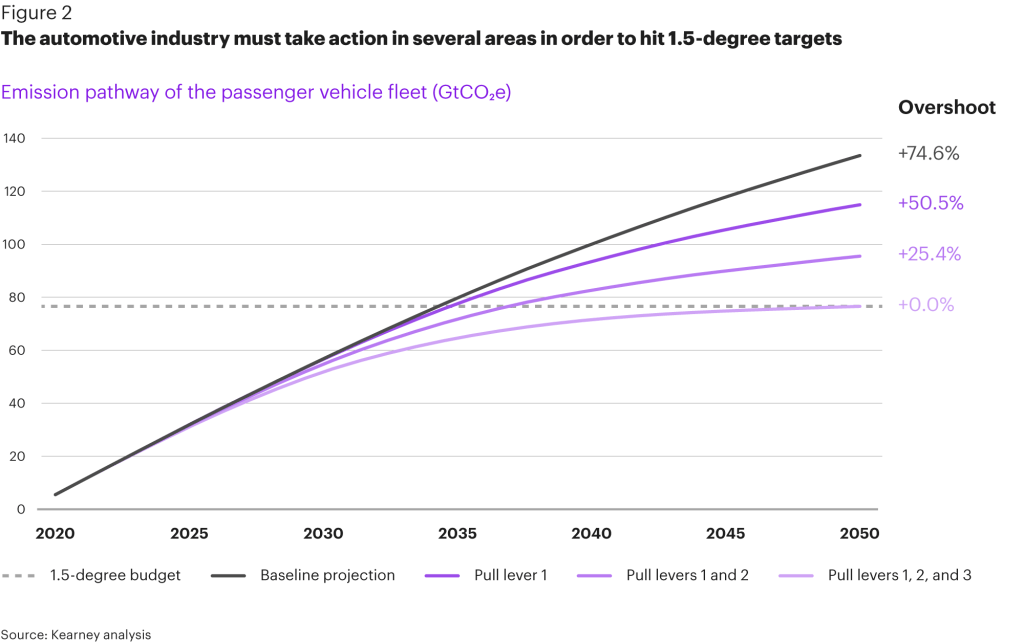

The third lever that needs to be “pulled” in order for the global car industry not to exceed its budget would see automotive supply chains reducing their greenhouse gas emissions by 81% by 2032, with particular emphasis required on reducing the emissions impact of manufacturing electric vehicles compared with their combustion-powered equivalents.

“Today, supply chain emissions for an EV are approximately 35-50% higher than for ICE [internal combustion] vehicles, primarily due to [the] batteries,” the report claims.

At present, battery manufacturing accounts for some 27% of an electric vehicle’s manufacturing emissions and, according to the report, these production process need to be 100% electrified by 2032, with all material extraction and processing powered by a fossil-free mix.

With steel, iron and aluminium making up 40-60% of the average car’s supply chain emissions, a major effort on the part of manufacturers is needed to reduce the quantity of CO2-intensive materials used through an emphasis on recycling or on replacing those materials with lower-impact alternatives.

Technologies such as more efficient furnaces, the use of inert anodes in batteries, carbon capture and the generation of fossil-free electricity and hydrogen were all suggested as other ways to clean up automotive supply chains.

Only with all three areas addressed does the global car industry face any prospect of staying within its carbon budget, according to the report, and getting there represents an “uphill battle”.

“Debate will continue regarding time frames, data variances and long-term targets, but the case for action is clear,” it says.

“Every year that passes without significant reductions is an opportunity lost and a setback from which we will have to work even harder to recover.”

Both Polestar and Rivian have invited other manufacturers to participate in a round-table discussion aimed at exploring ways in which a concerted effort can be made to address the challenges laid out in the report.

“The report’s findings are sobering,” said Anisa Costa, chief sustainability officer at Rivian.

“Our hope is that this report lays the groundwork for the automotive industry to collaborate in driving progress at the pace and scale we need — and ideally inspiring other industries to do the same.”

Related articles

- After reading about the report on decarbonisation of the car industry, you might like to check out our review of the Polestar 2

- Take a look a Will Dron’s preview of the 872bhp Polestar 5

- And click here if you want to see our guide to all the car makers’ electric vehicle plans

Latest articles

- Omoda 5 prototype review: Bargain family SUV is solid first effort for new Chinese brand

- Dacia Duster 2024 review: Rugged, affordable SUV modernised with electrification and quite the glow up

- Audi A3 Sportback 2024 review: Softly, softly, catchy premium hatchback buyer

- New electric-only Mini Aceman fills gap between Mini Cooper hatch and Countryman SUV

- Tesla driver arrested on homicide charges after killing motorcyclist while using Autopilot

- Porsche Macan 2024 review: Sporty compact SUV goes electric, but is it still the class leader for handling?

- F1 2024 calendar and race reports: What time the next grand prix starts and what happened in the previous rounds

- Aston Martin DBX SUV gets the interior — and touchscreen — it always deserved

- Nissan unveils bold look for updated Qashqai, still made in UK