Toyota aims for solid-state battery EVs with up to 750 miles of range by 2027

Lexus may get the tech first

Toyota has announced that it is hoping to have solid-state batteries ready for commercial use as early as 2027, potentially marking a huge breakthrough in electric vehicle (EV) technology.

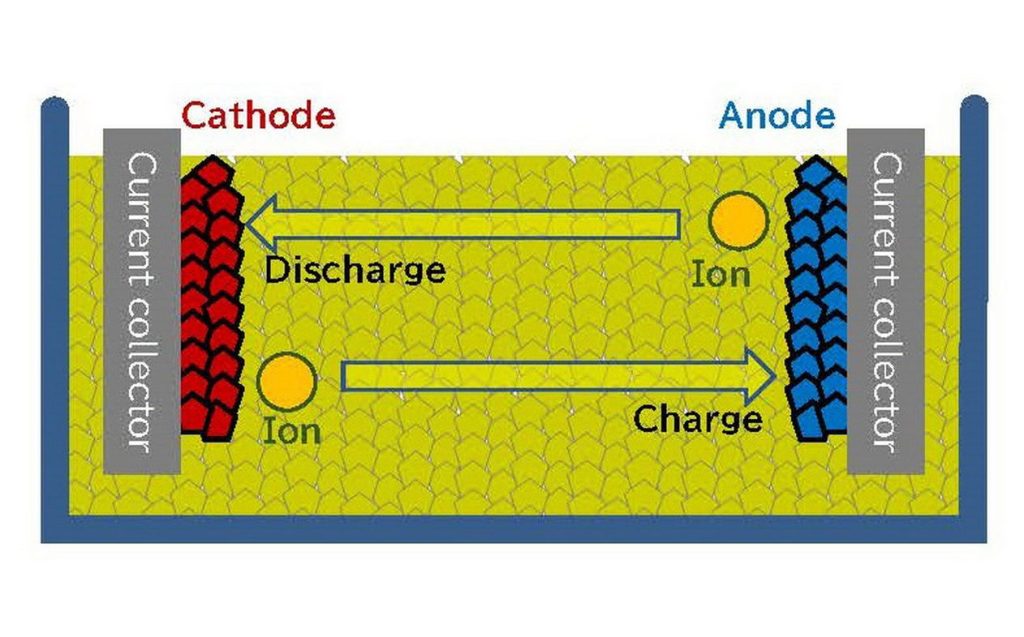

The Japanese company has been working hard on developing the current lithium-ion liquid electrolyte technology that is the norm in EVs on sale today in order to make its batteries cheaper to build, quicker to recharge and also capable of delivering a greater one-shot driving range.

But the real holy grail for EV battery technology is getting a solid-state battery to be ready for mass public consumption.

Up to 750 miles of range from your EV

Toyota has claimed it is ready to manufacture solid-state batteries at the same rate it can manufacture existing batteries for EVs, which is the key aspect in commercialising the technology.

If Toyota succeeds in its mission in getting solid-state batteries to market by 2027, EV buyers could be looking at cars that will be capable of at least 600 miles to every charge — and, in the case of an even more advanced second-stage solid-state battery, the manufacturer is targeting 745 miles and more from a single charge.

Another added benefit of solid-state batteries is they are less susceptible to fire than current lithium-ion liquid batteries.

And rapid charging times are also reduced, with a 10-80 per cent replenishment of the battery’s state of charge (SoC) coming down to around 10 minutes, instead of 20-30 minutes as current technology allows.

Manufacturing process key to success of technology

The problems previously with solid-state batteries have related to scalability. Producing enough of the new battery type in large volumes is expensive and difficult, while the batteries themselves are extremely sensitive to both moisture and oxygen — complicating the production process.

They also need to be held together at great mechanical pressure to prevent the formation of dendrites, metal filaments that can cause short circuits within a battery’s make-up.

One of the perceived drawbacks with a solid-state battery is that, despite its improved performance in various areas of EV usage, it conversely is said to have a much shorter operational life. However, Toyota says it has made significant developments in this regard to have negated that issue.

However, at last month’s launch of the Lexus LM, a new luxury people carrier from Toyota’s sub-brand, the company’s national brand manager for the UK said that a breakthrough had been made and Lexus was planning to start mass-production of solid state batteries within three years.

“It’s expected to go into production ’26-ish,” Paul Vecchione told Driving.co.uk. “The traditional advantages are that they’ve got higher capacity, they charge faster and release the energy faster. The difficulty has always been productionising them and ensuring you’ve got the durability. And that’s the threshold that we passed now.”

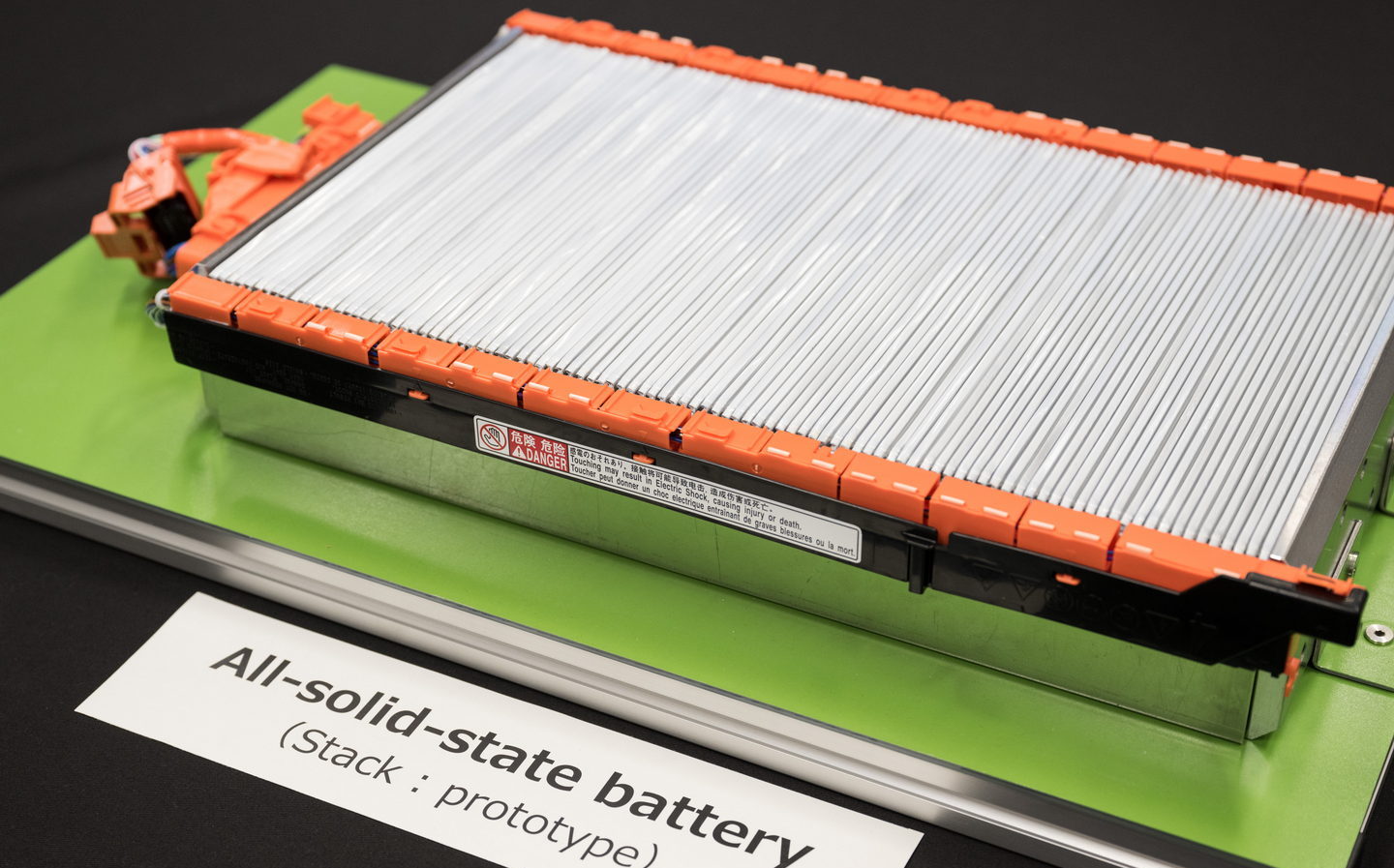

According to a story in the Financial Times, Toyota says the most crucial technology in the production of solid-state batteries relates to the assembly process, as multiple layers of cathode-anode cells must be stacked quickly and incredibly accurately, without damaging any of the materials involved.

This is where Toyota says it has made its breakthrough, with an engineer for the company quoted in the FT as saying: “In terms of the stacking speed, we are almost there. We are going to roll out bigger volumes and check the quality.”

It is likely that Lexus would be the first to use the solid-state battery packs. Vecchione told Driving.co.uk that the first models to receive solid state batteries are still to be confirmed but it would perhaps initially be the hybrid line-up before the pure-electric cars.

Lexus is also arguably better-suited to introduce solid state first, as it has already launched more electric models — such as its UX 300e and RZ SUV — ahead of Toyota, which currently sells the bZ4X as its only dedicated electric passenger car in the UK, and if solid state batteries are more costly then Lexus is better able to market such vehicles.

However, when pressed on costs by Driving.co.uk, Vecchione simply said the brand was “working through the cost basis” at the present moment and didn’t have anything further to say.

New battery plant — but will dates be pushed back?

Toyota has already given tours of its Teiho plant in Japan’s Aichi prefecture to key stakeholders. It is in Teiho where the company plans to build solid-state batteries in commercial quantities.

However, some caution must be sounded with Toyota’s announcement. The company has had to push back development timetables for the technology in the past, which means that EVs with this technology being available for sale by 2027 might not be set in stone just yet.

And despite the breakthrough claims, there may still be problems with scalability and quality. Toyota’s recently announced partnership with energy group Idemitsu Kosan is reportedly still working on a solid-state battery material called sulphide solid electrolyte, which addresses the durability issue of a solid-state battery.

Toyota’s president Koji Sato said at a news conference earlier this month that solid-state battery production volumes would remain small in 2027, adding: “I think the most important thing at the moment is to put out [the solid-state batteries] into the world and we will consider expansion in volume from there.”

A choice of battery types

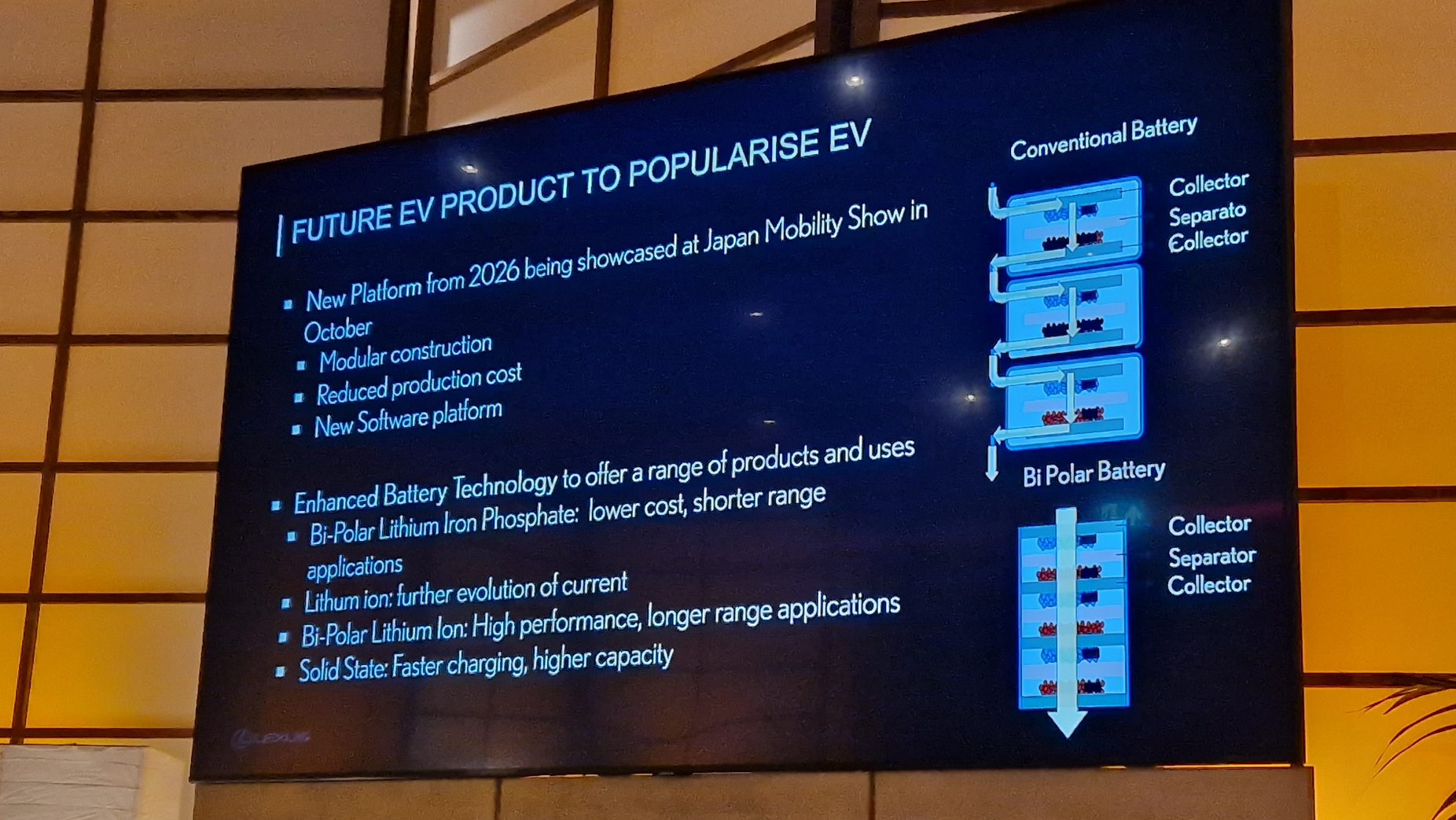

Nevertheless, Toyota has recently announced multiple different stages of advanced battery technology for its forthcoming EVs. Takero Kato, president of Toyota’s new battery plant, said: “We will need various options for batteries, just as we have different types of engines. It is important to offer battery solutions compatible with a variety of models and customer needs.”

To that end, Toyota expects 1.7 million of the 3.5 million EVs it sells globally by 2030 to use one of four new battery technologies.

Sticking with liquid electrolytes, Toyota’s ‘Performance’ battery is planned for market from 2026. It is claimed to increase the driving range (currently around 310 miles with the bZ4X) to around 500 miles, while also reducing the cost of the production of the battery itself by 20 per cent. Rapid recharge times will be around 20 minutes.

The ‘Popularisation’ battery uses lithium-iron phosphate, a cheaper core material, and Toyota’s bipolar internal construction — instead of monopolar — to increase the driving range of the current bZ4X battery by 20 per cent, while reducing costs by up to 40 per cent.

And it even has plans for a high-performance lithium-ion battery with the bipolar inner structure, said to give up to 621 miles of driving range on a single charge, although it is not due until 2027.

The first-gen solid-state battery would give the same sort of range as this high-performance lithium-ion liquid battery, but would be faster to recharge. And Toyota is already working on targeting a 50 per cent improvement in cruising range, compared to the Performance battery, with a second-stage solid-state battery – which would give the 750 miles claimed between charges.

One of the key areas in making EVs go further on their charge, regardless of their battery chemistry type, is reducing vehicle weight and reducing aerodynamic drag. To that end, Toyota is also working on making its battery packs lower in height, which in turn will make the vehicle’s body/frontal area lower and thus improve range.

So where the current bZ4X battery is around 150mm tall, Toyota is targeting reductions to 120mm for many of its next-gen battery packs, with a 100mm application possible for sportier EVs which need a lower hip-height for occupants.

Related articles

- If you found the news about Toyota’s solid-state battery tech interesting, you may want to read about the radical looking Toyota C-HR

- Keen to go electric? Here are the top 10 longest-range electric cars

- Read our guide to all the car makers’ EV plans

Latest articles

- Omoda 5 prototype review: Bargain family SUV is solid first effort for new Chinese brand

- Dacia Duster 2024 review: Rugged, affordable SUV modernised with electrification and quite the glow up

- Audi A3 Sportback 2024 review: Softly, softly, catchy premium hatchback buyer

- New electric-only Mini Aceman fills gap between Mini Cooper hatch and Countryman SUV

- Tesla driver arrested on homicide charges after killing motorcyclist while using Autopilot

- Porsche Macan 2024 review: Sporty compact SUV goes electric, but is it still the class leader for handling?

- F1 2024 calendar and race reports: What time the next grand prix starts and what happened in the previous rounds

- Aston Martin DBX SUV gets the interior — and touchscreen — it always deserved

- Nissan unveils bold look for updated Qashqai, still made in UK