Ariel and Cosworth create high-performance electric road car prototype with 1180bhp and 150 miles of range

Behold the baby Batmobile

Ariel Motors, the small Somerset car-maker best known for its exoskeletal Atom and Nomad models, is to debut a new prototype for a “high-performance electric road car” at the Cenex-LCV trade event in Bedfordshire next week.

Built in collaboration with Cosworth, the Hipercar (short for High Performance Carbon Reduction) has been developed using government funding through the Coventry-based Advanced Propulsion Centre.

With its coupé body style, the Hipercar’s cockpit is less exposed to the elements than Ariel’s other models and the styling appears to be a miniature blend of Bugatti, Batmobile and Blackbird spy plane, the latter influence, at least in part, justified by one particular element of the powertrain.

That powertrain has been sourced from Cosworth-Delta (Cosworth’s electric propulsion division) with a requirement from Ariel that the Hipercar should be track-capable as well as a competent road car.

One of the design briefs, according to Cosworth, was that the battery needed to be able to supply enough power to the motors to enable the Hipercar to beat lap records set by combustion-powered cars. A lot of work also went into developing an effective system for cooling the powertrain during use on track where heat can be more than ten times that generated during even fast road use.

The battery set-up is Delta-Cosworth’s patented Cylindrical Scalable Modular system that enables the firm to produce battery packs in any size and shape, especially useful when it comes to supplying small companies producing low-volume models.

“Developing battery technology for the Hipercar programme has provided the team a hard challenge,” said Simon Dowson, managing director at Delta Cosworth.

“Not only have we had to develop ultra-lightweight structures to manufacture the battery pack, but also maximise the cells performance as much as possible.

“We have also built upon our already existing vehicle integration capabilities, by collaborating with the Ariel engineering team to ensure our battery pack fits into the tightest dimensions, while keeping the mass as low as possible to keep the vehicle light and agile.

“The car has performed as expected in testing and we are excited to see how much performance we can extract from the car with further testing.”

There’s currently 62kWh of battery storage sending power to four 295bhp electric motors (one for each wheel) meaning 1,180bhp on tap in total and 150 miles of range. Acceleration from 0-60mph is, according to Ariel’s simulations, is in the region of 2.09 seconds.

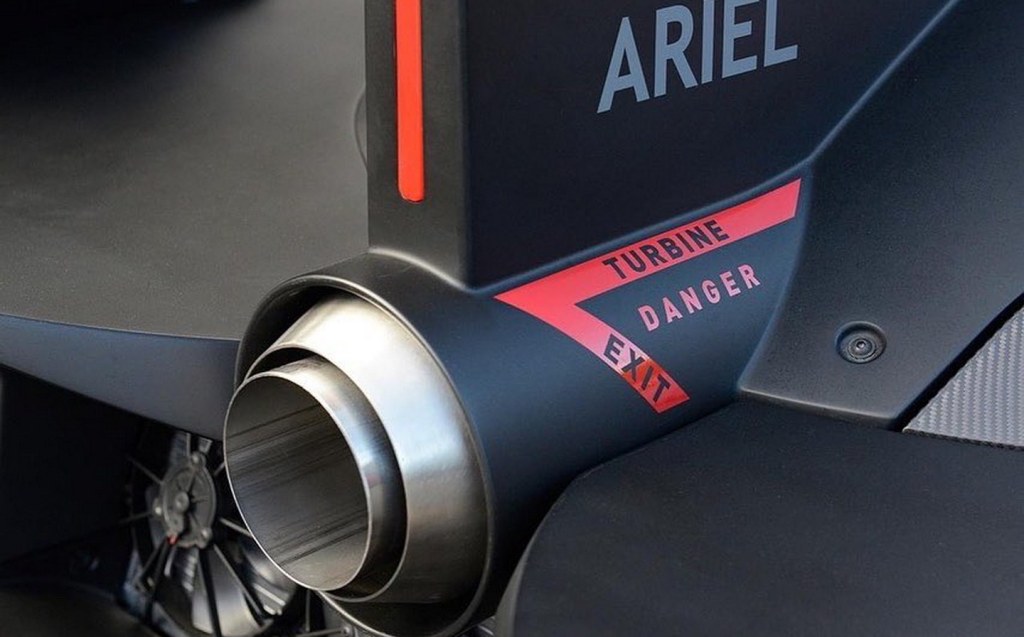

None of that seems especially unusual in today’s world of high-powered hypercars, but what’s poking out from the rear beneath the double tailplanes and endurance racer fin very much is.

Cosworth’s catalytic generator is small micro-turbine range extender that can charge the battery on the go, and which can use nearly any type of fuel. Though the company says that for now it is only running the system using ordinary petrol, it could also use sustainable fuels such as synthetic e-fuels or, in the future, hydrogen, something that is already in development.

When running, the catalytic generator, said Ariel, does sound a bit like a jet engine with a characteristic turbine whine meaning that there’s at least some validity to the out-there aircraft-influenced styling.

The prototype’s body panels are 3D-printed, but according to Ariel, they’ll be all-carbon on the eventual production version.

“With Hipercar we have pushed Cosworth to the extremes of current technology and capabilities,” said Simon Saunders, director at Ariel.

“We do have the most difficult requirements, demanding maximum power, lightest weight and ultra reliability in the smallest package possible.

“On top of this we required a track capability for the car which meant Cosworth had to come up with new solutions in battery pack design.

“The rigorous test programme to date has demonstrated that our requirements are being met and we look forward to continuing into production with Cosworth as a partner.”

Related articles

- After reading about the new Ariel Hipercar, you might be interested to read that the new BMW M3 Touring was unveiled in Goodwood

- Or check out the bonkers 1973bhp Ford Supervan that also debuted in Goodwood

- Read all about the 872bhp Polestar 5 electric GT

Latest articles

- Mini Cooper SE 2024 review: All-new electric hatchback is playing to the crowd

- Jeep Wrangler 2024 review: Impressive off road but you’d still have to be a committed contrarian to buy one

- Around 500 Ford workers in UK could go on strike over cost-of-living pay dispute

- Durham solar car team to take part in 24-hour race with smart tyres and night-driving solution

- Jim Farley, Ford’s racing driver CEO: Porsche has outsmarted us in the past; now it’s time to outsmart them

- Scalextric adds Ford Anglia from Harry Potter, John Wick’s Mustang and a gold James Bond DB5

- Best-selling cars 2024: The UK’s most popular models

- New Volkswagen California camper based on car underpinnings and available as a hybrid

- F1 2024 calendar and race reports: What time the next grand prix starts and what happened in the previous rounds