Secrets of the laboratory: Jaguar Land Rover's technology of the future

Deep within the car maker, engineers are changing the way we'll drive the vehicles of tomorrow

LASSERS THAT can check it’s safe for you to proceed, a virtual windscreen that can display the perfect racing line, cars that can read your mind, a 3D instrument cluster you can read without special glasses, features you can operate with a wave of the hand…

It sounds like the stuff of a science fiction novel but in deepest Warwickshire these technologies, and more besides, are a reality, and some are even on the brink of production.

Browse NEW or USED cars for sale

They’re being developed at Jaguar Land Rover’s research and development facility at Gaydon, a place filled with 6,000 busy employees and world-beating design and engineering departments.

The developers’ work will find its way into an impressive number of new models ‒ over the next five years, one major new car will be released every six months, in addition to 50 “major product actions”. These will include major design facelifts, as well as new versions of existing models.

Next year, Jaguar’s new, aluminium-bodied XE, a rival to the BMW 3-series, will be launched taking the brand back into a key sector it last occupied with the underwhelming X-type.

All these new models will require lots more people to buy them, and JLR is sure it knows who they are and what they will want. It forecasts a doubling of the world’s so-called mega-cities (from 12 to 24) by 2025 and a consequent increase in the size of an affluent middle-class.

“These people will want their cars to be capable, clean, connected, desirable and smart,” said Dr Wolfgang Epple, director of research and technology at JLR. “We will use new technology to make our cars the most desirable on the market.”

That desirability will be aided by some of the leading-edge new tech he and his team will pack into Jaguar and Land Rover vehicles over the coming years. In deepest Warwickshire, science fiction is becoming reality.

Seven Jaguar Land Rover technologies that will blow your mind

Virtual windscreen

Sure to be a hit with F-type drivers. Like a computer racing game, the perfect racing line is projected onto the car’s windscreen complete with braking indications. Can display a “ghost” reference car, too, while competitor’s car with same tech could also be uploaded and displayed. In addition, can show virtual cones to aid obstacle avoidance in driver training.

Gesture control

Smartphone technology applied to the car’s interior could allow occupants to operate key functions with a sweep of the hand or finger, rather than using switches and buttons. Unlike smartphones, it is sensitive up to 15cm from surface. Sunroof operation is closest to sign-off (possibly as early as next year) but other functions including window blinds, rear wiper and sat nav are also on the way.

3D instrument cluster

Displays instruments and even music albums in specs-free 3D thanks to head and eye-tracking technology that supplies each eye with two slightly differing angles of the same image. Particularly effective when used to display camera images from the outside of the car where currently, two-plane images produced by, say, a reversing camera, give no perception of depth. In this role, it could replace mirrors.

Self-learning car

JLR’s ambition with this technology is “zero accidents”. It’s all about the car taking over many of the tasks that would otherwise distract the driver, as well as learning their driving style. Services include: setting the mirrors, steering wheel and seat to the driver’s preferences before they’ve opened the door; reviewing their schedule and pre-setting the navigation system according to real-time traffic conditions; adjusting the cabin environment according to the event the driver has been at or is going to, and based on selections the driver has made previously (for example, after the gym setting the massage function); phoning through the driver’s apologies if they’re going to be late to a meeting. In addition, it can apply the driver’s driving style to the car’s Auto Adaptive Cruise Control (AACC) system. “The self-learning car will ensure that any future intelligent car remains fun and rewarding to drive as we move closer to more autonomous driving over the next 10 years,” said Dr Epple.

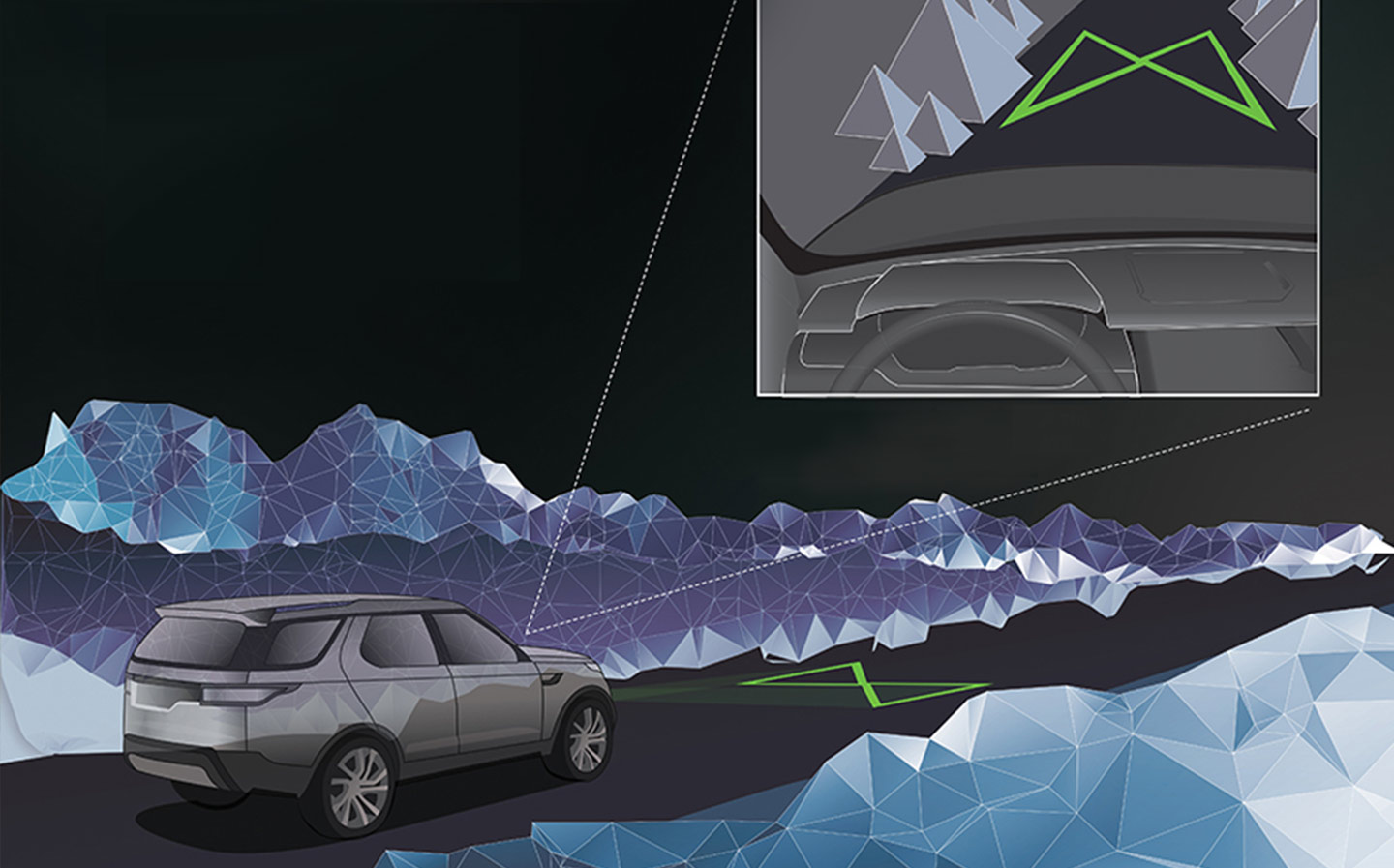

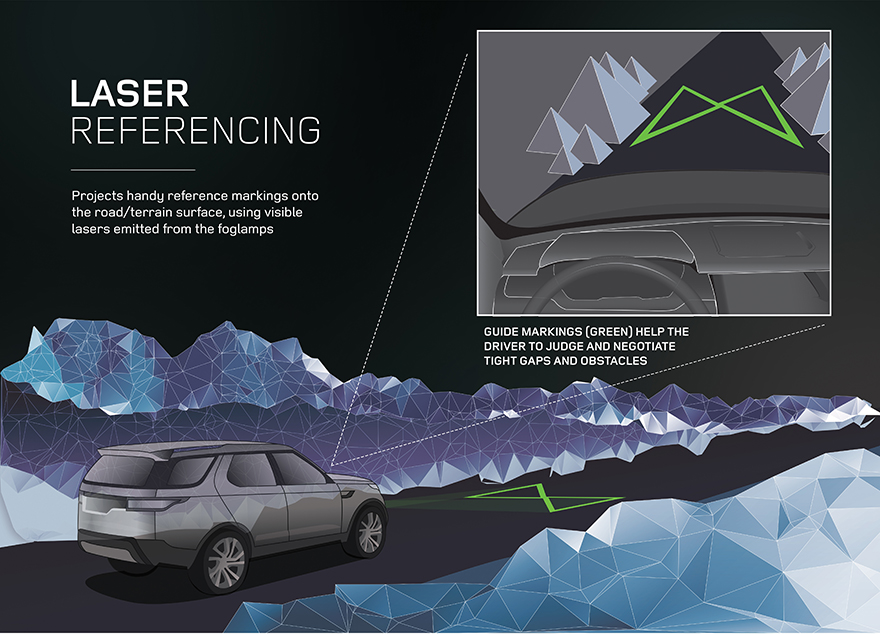

Laser referencing

Lasers project guide markings showing the width of the car onto the road ahead so the driver can see whether the vehicle will fit through a narrow gap. They can also produce a contour map of the terrain so the driver can navigate a way through. The same technology can also be used to measure the depth of standing water before the vehicle enters it (JLR’s existing Wade Aid system uses sonar, and only works when the vehicle is in the water).

Transparent Bonnet

Already seen on the Land Rover Vision Concept at the New York show in April, this technology uses cameras to project an “augmented reality view” onto the windscreen of the area immediately beneath the car’s bonnet. As a result, the driver can see not only the terrain but also which way the front wheels are pointing.

Ingenium engine

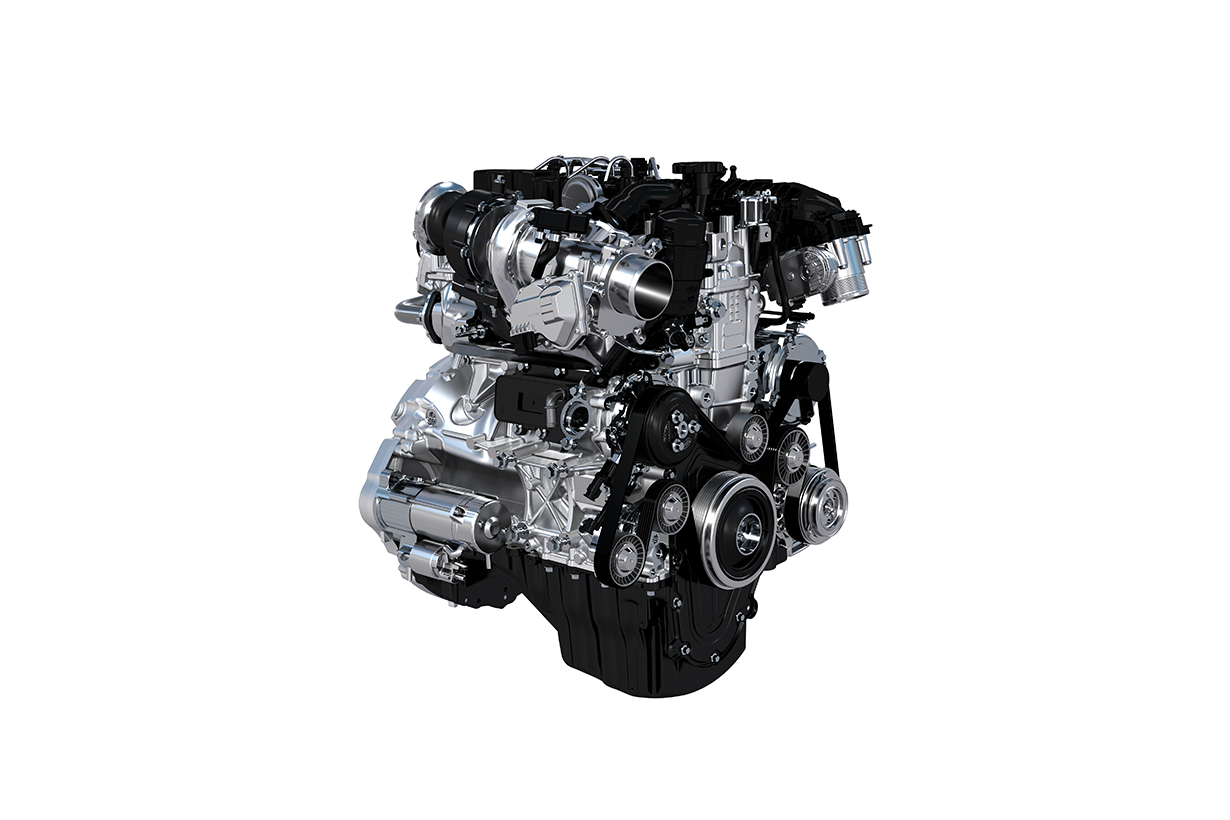

This new family of engines will mark JLR’s return to engine manufacture (the company has built a £500m production plant near Wolverhampton) and will power the XE when the new saloon is launched next year. Initially launched in 2-litre petrol and diesel form, the lightweight powerplant can be scaled up or down in capacity as required by future applications across a range of JLR vehicles. It can work with front, rear or four-wheel-drive transmissions. Its role, in combination with future hybrid technologies, is to help JLR achieve the EU’s required average emissions of 100g/km by 2020. The company is currently at 180g/km.

Virtual reality engineering

One of the most amazing features of JLR’s R&D base at Gaydon is the Virtual Innovation Centre. You put on 3D specs and stand before a large screen that depicts a whole car or just a detail such as the engine. An engineer alongside, holding a joystick and wearing a projector, then manipulates the image in 3D. The technology allows JLR to design prototypes to the last detail, without making them in solid form, and to see how they look and work from all angles.

Driving was shown how the car maker used the system to make the XE engine easier to work on by locating components such as the oil filter and catalytic converter in more accessible places. Engineers said the system revealed how the original Evoque prototype had insufficient rear headroom. Using it, they were able to lower the car’s underfloor space, where the exhaust pipe and transmission sit, and create extra cabin room.