Revolutionary art car painting robots suggest a future where no two vehicles look the same

Could every car in the future be unique?

The world’s first robot that can paint complex art cars has been unveiled, and its introduction may have profound implications for the future of car design.

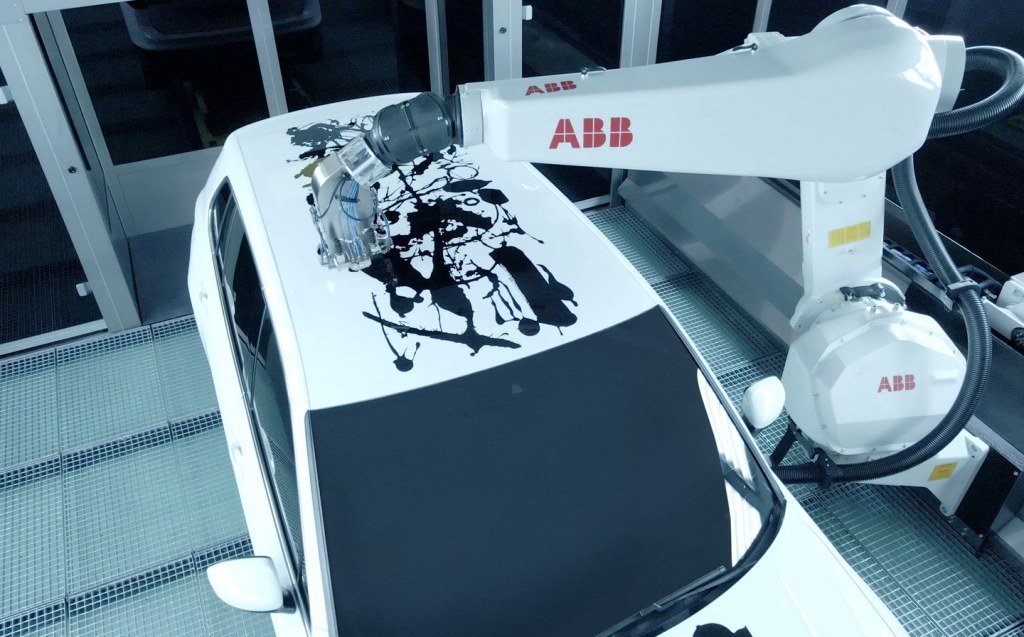

In order to demonstrate the capabilities of its latest PixelPaint robot, Swiss-Swedish automation company ABB commissioned two artworks to be applied to a vehicle using the machine — the first from eight-year-old Indian artist Advait Kolarkar and the other from the digital design firm Illusorr.

Kolarkar’s creation, a monochrome abstract piece entitled Zebra Utopia, inspired by a zebra-striped Pegasus flying though a dreamland, was scanned and then perfectly recreated by the robot onto the bonnet and roof of what appears to be a Volkswagen Tiguan — used for the demonstration.

The artist, whose works have fetched up to £100,000 and who currently has his first solo show at the Gagliardi Gallery in Chelsea, was highly impressed by the process.

“I couldn’t believe a robot was painting an artwork for the first time ever,” he said.

“And it wasn’t just any artwork: it was my artwork. I think art and robots have a similarity. They both interact with the world, and they have the power to change the world for better.”

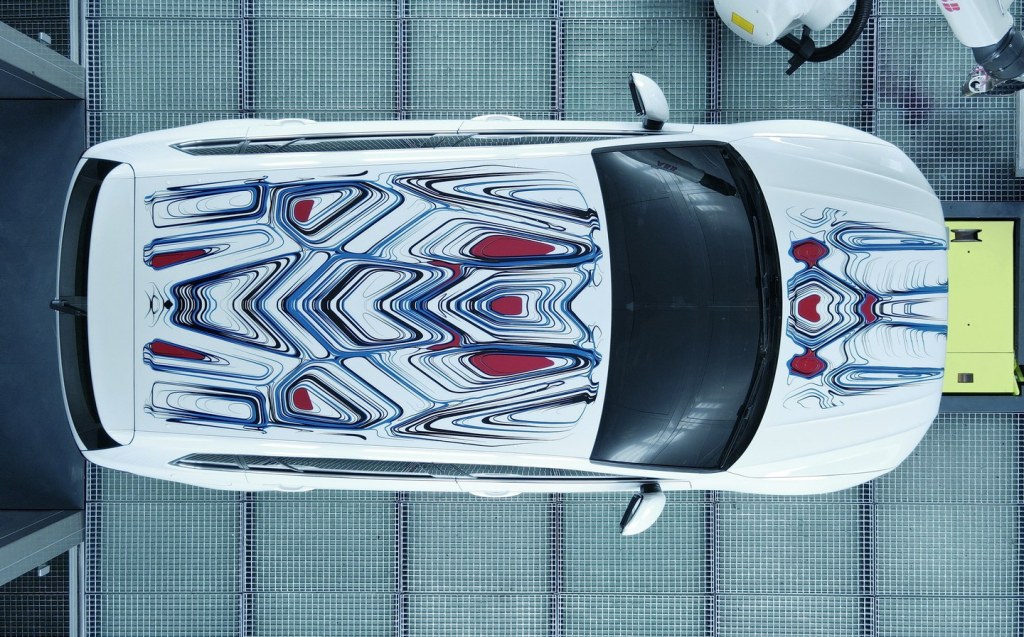

The second piece by the Illusorr collective (which designs figures and artwork for the Metaverse) was created digitally and unlike Kolarkar’s piece included three colours in a futuristic design inspired by nature, wind, speed and the airflow around the car.

“You can paint on a car with traditional techniques, but some artworks require a robotic execution, because a human eye or human hands can’t execute that kind of drawing level of complexity,” said one of Illusorr’s founders, Begüm Aydinoglu.

Unprecedented accuracy

That level of complexity is down the design of the new robot paint heads, which ABB says will be coming into use in the next year or two.

“Each PixelPaint has 1,000 individually controlled nozzles similar to an inkjet printer,” explained Sami Atiya, president of robotics and discrete automation at ABB.

“The paint is carefully controlled and because our PixelPaint is so accurate the paint heads track just millimetres from the body. This means that 100% of the paint is applied to the car. PixelPaint is the future of customised automotive painting.”

As Atiya suggests, the development of paint robots capable of highly complex individual designs raises big questions for the future of car design, including the possibility that car buyers could be able to upload their own paint designs, perhaps through an online configurator and have them replicated on the production line.

The future of car customisation

This is something that Ian Callum, head of the Callum design firm and creator of, among many other things, the Aston Martin Vanquish and Jaguar F-Type, is particularly excited about.

“It’s incredible. It will get to the point where no two cars that you buy — albeit they might be the same car line, the same brand — they will not be the same.

“Whether it’s out of choice of features or whether it’s a very individual paint job. I do believe, looking at the way this works, that it will – it could become – you know, beyond something that’s elite and something that’s very niche. I think you can go onto semi-mass market cars.

“It’s obviously a special order of some kind. It will probably end up on a special paint line within a mass production process. But I think I can see this being applied to cars that you and I could buy. I think it’s extremely exciting.”

Rather than such high levels of customisation being just a flight of fancy, Callum believes that there’s a strong business case to be made for car makers employing robots such as ABB’s PixelPaint system.

“I think the large car companies now realise that personalisation is also a money-maker. Because people are happy to pay for it.

“When most people buy a car they do want to add their own personal touch. And quite often they’re very, very happy to pay for it. And that’s in fact how car companies make money, it’s all the personalisation, all the features, all the accessories people might add to the car, is where a lot of their margins come from.

“This just is another opportunity to add margin to the product. And I’m sure if the pricing is right — and I’m not talking about a cheap alternative — I’m talking about it’s something that people are prepared to pay perhaps, you know, a couple of thousand pounds or even more for it. Then it’ll be well worth it as a business case.”

Whether individual factory customisation takes off may depend on what segment of the car market in which it makes its debut. Buyers of expensive ultra-luxury cars such as Rolls-Royces and Bentleys may be willing to pay quite a lot more money to stand out from the crowd, though the same may not be true at the other end of the market.

In 2017, MINI launched its Yours Customised service whereby buyers could specify 3D-printed polymer parts such as dashboard inlays, door-sill projectors and side scuttles bearing the owner’s individual designs or lettering.

The parts were produced in Germany within a few weeks of ordering and could be fitted by either the owner or a dealer and, at the time, it was hailed as an exciting development in both 3D printing technology and car customisation. By 2021, however, the project had been quietly shelved.

Related articles

- After reading details about the ABB painting robot, you might be interested to see how Ford replaces human drivers fro robots in certain conditions

- heck out the self-driving ‘robotaxi’ unveiled by Amazon-owned Zoox

- Or you might like to see how Hyundai has developed a robotic exosuit for production line workers

Latest articles

- Ford E-Transit Courier 2025 review: Compact electric van bolsters Ford’s eco creds … for a price

- Aston Martin takes DBX super-SUV to new heights with 717bhp variant

- Hot topic: 13 things drivers should not leave in a car in warm weather

- Skoda creates digital showroom on Amazon in European first

- Porsche 911 Carrera S 2025 review: Harder, better and faster – but is it the best 911?

- F1 2025 calendar and race reports: The new Formula One season as it happens

- Seven great automotive events to visit this summer, from F1 to art and champagne

- Watch new Porsche 911 GT3 smash Nürburgring record for manual cars

- Skoda Elroq 2025 review: Czech carmaker can’t seem to miss with its electric family cars