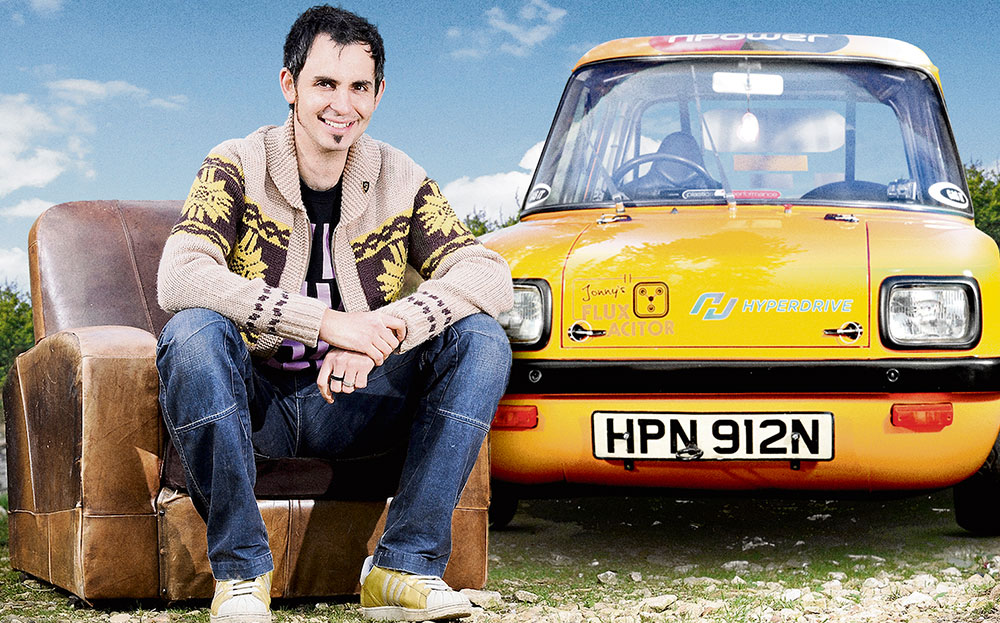

Jonny Smith: electric Flux Capacitor v Nissan GT-R

Laugh if you like, but it’s given Tesla a hell of a shock

BACK IN 2012 — before the electric Formula E racing series and Tesla’s rapid Model S — I wrote a piece for The Sunday Times about starting a pet project to build an electric hot rod using a historic electric vehicle that few remember.

View the electric cars for sale on driving.co.uk

The base car was an Enfield 8000, a timid-looking British eco city car made by a branch of the Enfield motorcycle company. Spurred on by the oil crisis of the early 1970s, Enfield constructed the 8000s on the Isle of Wight and sold most of them to the Electricity Council, which used the cars to promote electric transport.

The national grid was preparing for an influx of electric cars as people weaned themselves off oil. Except that influx was more of a dribble. Although the aluminium-bodied, rear-wheel-drive Enfield wasn’t a bad car (it could cover 35-55 miles on one charge and boasted its own charging system, a heated windscreen and run-flat tyres) it was simply too pricy. Sound familiar? Alas, only 120 were made.

Mine is chassis number 003, one of about 30 survivors. Severely damaged in the past, it was ripe to have its dead electrics removed and to receive a 21st-century, cutting-edge, high-voltage transplant.

The reason? I had entered the FIA/FIM European championship, the toughest competition in the drag-racing calendar, at Northamptonshire’s Santa Pod quarter-mile track. The Enfield — which is 8in shorter than the old Austin Mini and 4in shorter than the original Fiat 500 — had embarked on the biggest challenge of its life. It was on course to become a record-breaker.

Some of you may be chuckling at the photos of the vehicle we named the Flux Capacitor (with a nod to our sponsor, Adrian Flux insurance). Good. That was precisely the point of choosing a 9ft car to turn into a dragster packing more than three times the torque of an Aston Martin Vanquish. We Brits love an underdog. My hope was that it could beat Elon Musk’s ever-evolving Teslas as the fastest road-legal all-electric car, while reminding people that electric vehicles were nothing new in the car world.

For the Street Eliminator category in which we were racing, the rules for qualification stipulated that every car must have an MoT, run on normal tyres (not slicks) and complete a 25-mile street cruise. Break down and you’re out. Wipers stop working? You’re out. Fail scrutineering and you’re out.

Bear in mind the yellow midget was competing against piston-powered twin-turbo V8 creatures with between 1,000bhp and 3,000bhp. Forget Bugatti Veyrons and McLaren P1s — these are the fastest cars in the world. From a standstill, several can pass 200mph in seven seconds. Gulp.

At our first drag-race meeting, we scored a 12.62-second quarter-mile at 101.65mph. Fast, make no mistake. Three years ago that would have been within spitting distance of the fastest Tesla, but the American electric car maker’s Model S P85D has since been recorded in the mid-11s. We needed to go faster.

My twin 9in DC electric motors were built by Olly and Sam Young of Current Racing in Hungerford, Berkshire, who are the only other e-drag racers in Britain. They also generously shared eight years of invaluable electric vehicle (EV) race knowledge.

Finding the batteries had been a time-consuming — not to mention wallet-draining — mission. These are key to the car’s performance; for drag racing they need to be able to discharge a colossal amount of power in a short amount of time without turning into lava. My 12-month search ended after a Twitter chat with a company in Sunderland, Hyperdrive Innovation. It was able to track down lithium-ion batteries in South Korea and had the necessary military account to buy them — which I didn’t. (These batteries are typically used to start the engines and run the mini-guns on Bell SuperCobra attack helicopters. But you probably knew that.)

The Enfield originally carried 660lb of lead acid batteries, producing 48 volts and 150 amps. Today? Hyperdrive’s 144 4.2V lithium-ion “pouch” cells have been carefully packaged beneath the bonnet, weighing just 330lb and producing a maximum of nearly 400V and 2,400A.

We passed 105mph, signalled by the swift departure of the side windows, which were sucked into the slipstream

Dealing with the car’s high voltage has been a huge educational process.Rather than risk a shock of biblical proportions, we decided to cover the Enfield’s live battery terminals with Lego and now wear slightly fetish-style rubber gauntlets when working on it.

Of course, there have been a few teething problems. Such as when I cracked the windscreen and discovered that replacements were as rare as pterodactyl’s teeth. To make a new one, we had to produce a costly master mould.

Then there was the time we passed 105mph on the drag strip, an achievement signalled by the swift departure of the side windows, which were sucked into the slipstream.

Then a faulty ECU lead meant we spent one race weekend sitting in my mate Nick’s camper van, listening to Simon and Garfunkel and eating Jamaica ginger cake. But that’s racing — if it were easy, everyone would build electric dragsters, right?

The weekend after our first run we were back at the track. Many said our car wouldn’t grip properly at the start or hold straight at high speeds. Thankfully, they were wrong. The Flux Capacitor raced against a British touring car competitor and left it for dead. We finished the event with a personal best of 11.67 seconds at 109mph.

Fast. Ferrari fast, in fact. Quicker to 60mph than a Formula E electric racing car. But we knew the Flux Capacitor had more in it.

Qualifying for the European finals, we went even faster, with an 11.27-second run at 118mph — matching a Porsche 911 Turbo S and Nissan GT-R. I never thought it would go so quickly. Now dyed-in-the-wool, greasy-palmed drag racers were reaching out to shake my hand.

With gritted teeth we completed the 25-mile Saturday lunchtime road cruise among 16 deafening, gloriously smelly conventionally powered dragsters. This was a world first for an electric car. We limped back to the Santa Pod pits and prepped for the daunting first round of the Street Eliminator. I was up against a 2,500bhp Nissan GT-R and had two hours to fully charge up and prepare the Enfield for the run of its little life.

Untroubled by any poncy launch or traction control systems, I had 250V and 1,800A under my throttle pedal. They needed to count.

And they did, as is proved by a little slip of paper that looks rather like a till receipt. It reads: “10.84 seconds @ 121.11mph.”

Yes, I had lost the race against the colossal twin-turbo V8, but I had set a European record for a road-legal electric car in the process. Sorry, Elon.

The electric oddball had gone from standstill to 102mph in 6.9 seconds; its top speed on the quarter-mile was more than triple that of the original car. Its acceleration from standstill to 60mph put it in the same territory as the LaFerrari and McLaren P1 hybrid hypercars.

My favourite fact about the Enfield is that it was designed by John Akroyd, who went on to become the head aerodynamics engineer for Richard Noble’s 633mph, record-breaking Thrust 2. That still makes me chuckle.

But not as much as knowing that this Enfield — while quicker than most supercars — is tax-exempt and London congestion charge exempt, and still maintains its Hillman Imp steering system, Hillman Avenger door handles and Austin Allegro headlights. I’ve even put a phone charger in it.

Click to read car REVIEWS or search NEW or USED cars for sale on driving.co.uk